Golden luxury: how gold leaf is created and used

We tell how ultra-fine gold sheets transform any surface into a work of art — from gilded domes to sparkling makeup.

Gold is a rather soft and ductile material, it can be flattened in thin sheets without any cracks or holes.

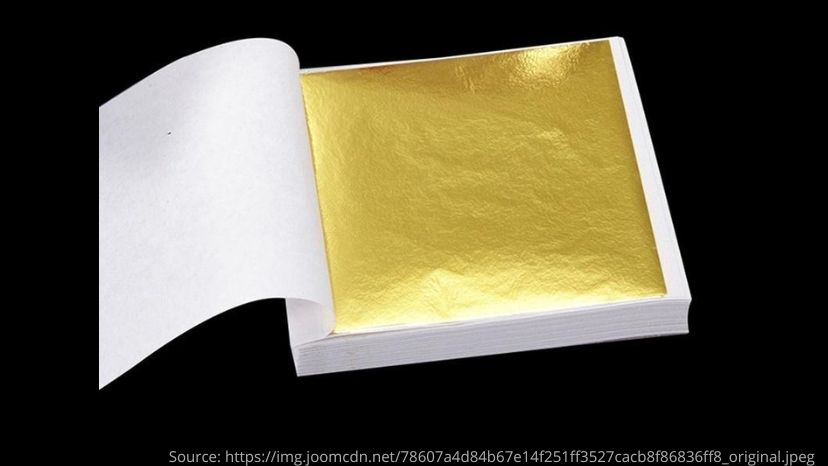

Gold leaf represents gold sheets, which are used in arts and crafts. When the surface is covered with these sheets, it seems that the whole object is made of the precious metal.

For the first time, the gold leaf technique was applied in China 1,700 years ago.

Technique of the gold leaf manufacturing:

- gold bar 20 cm long, 5 cm wide and 1 cm high shall be cast;

- the bar shall be flattened into a thin strip;

- the strip shall be cut into squares, then each of them is placed between the sheets of the translucent paper;

- the pile of gold squares layered with paper are stacked up in 100-300 pieces;

- the pile shall be placed under the heavy hammer, which hits it 2 thousand times with the certain load until each square has flattened out to the thickness of 0,0001 cm;

- a square shall be cut off from the flat gold cake and is put in the paper album, which may contain from 10 to 300 sheets of gold leaf.

In the photo: sheets of gold leaf are manufactured in the form of a book and sold in the jewellery stores and specialized shops intended for the artists and designers.

Three methods of hammering the yellow metal

- By using the manual labour: the hammerer hits the pile of gold squares with a heavy hammer. It is impossible to obtain gold sheets of the same thickness by using this method.Automatic hammering: a hammer hits the piles with consistent force, while a person moves the stack of gold squares beneath it.

- Automatic hammering: a hammer hits the piles with consistent force, while a person moves the stack of gold squares beneath it.

- Hammering is executed automatically, the pile of gold is shifted by the robot. The gold leaf of the highest quality is produced in Italian and German factories.

Application of gold leaf

- For gilding large-scale architectural facilities and sculptures: church domes, statues, monuments.

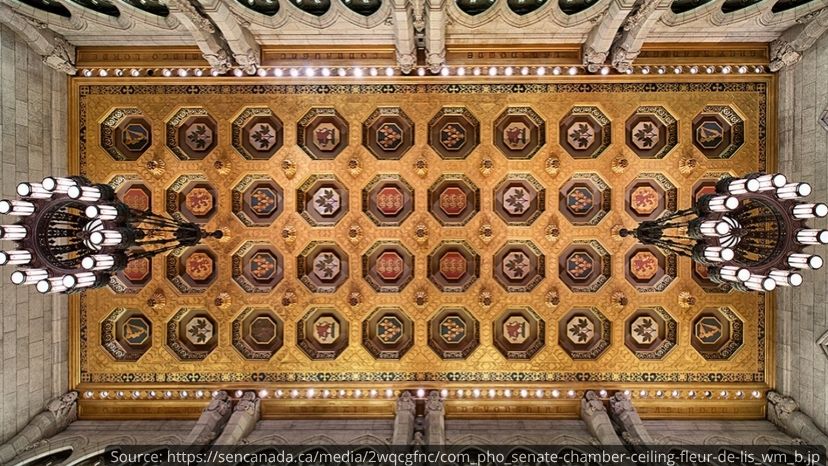

- As decorations for gilding exterior structures of the buildings and items of the inner decor: gold-plating of the columns, stucco work, balcony grids, staircases, furniture, ceilings.

In the photo: gilded ceiling of the Senate Chamber in the Parliament of Canada.

In the photo: gilded ceiling of the Senate Chamber in the Parliament of Canada.

- In the icon painting for drawing fine gold strokes on the icons.

- In the framing workshops for the manufacturing of gilded frames for the paintings and mirrors.

- Modern designers often use gold leaf as a clothing design element, while makeup artists apply it to create extravagant looks.

- Body wrappings, golden makeup and face masks on the base of gold leaf are very popular in the beauty industry.

- Precious desserts, sweets and cakes are often covered with gold leaf, gold particles can be added to various drinks.

In the photo: gold leaf is a new trend in the cake decoration.

In the photo: gold leaf is a new trend in the cake decoration.

Interesting facts:

- The usage of gold leaf is the only highly practical and durable method for gold covering of the various objects and surfaces.

- Due to the complexity of gold leaf production and the high price of gold leaf, brass leaf, also known as Dutch metal, (film made from various metal alloys) is often used for gilding items. Chemical compounds of tin, zinc-copper alloys, silver, and aluminum have a lustrous yellow color and imitate gold. Unlike gold leaf, brass leaf can oxidize and darken over time.

- Working with gold leaf is not easy since thin sheets are readily torn to shreds. Special tools and a certain level of craftsmanship are required to execute this work.

In the photo: the process of covering of the wooden stucco with gold.

In the photo: the process of covering of the wooden stucco with gold.

- Gilding increases the price of dishes and gives them a refined, exotic appearance, but it does not affect their taste. Edible gold has no smell or flavor. Gold-covered products are safe for digestion and do not affect the functioning of internal organs. It is believed that consuming edible gold leaf boosts a person’s vitality.

Read also: